Description

Paving Quality Control - Asphalt Thermal Profile -

Paving Quality Control – Why is it needed?

- Big profit if the lifetime of roads increase even 1 year more

- Cost reduction maintenance, repair or reconstruction of roads

Improving the quality of asphalt paving = Improvement of road construction

The new trend in supervision of projects road construction worldwide mandates compulsory delivery reference (As-Built) by the contractor upon completion of the project, which includes:

- its full record thermal profile of the laid surface

- the recording additional data screed (material-soil-screed temperature, environmental conditions, screed length, location)

Cracks due to thermal expansion of materials

THE heterogeneous recommendation of the asphalt materials causes cracks due to thermal expansions, which reduce the lifetime of the pavement by up to 40%!

Factors which contribute to the creation of thermal cracks during laying:

- Stand by for bitumen supply

- Frequent stops of the Finisher

- Changes to speed of the Paver

- Ugly ones environmental conditions

The thermal ones fissures are addressed by knowing the thermal profile of the laid surface

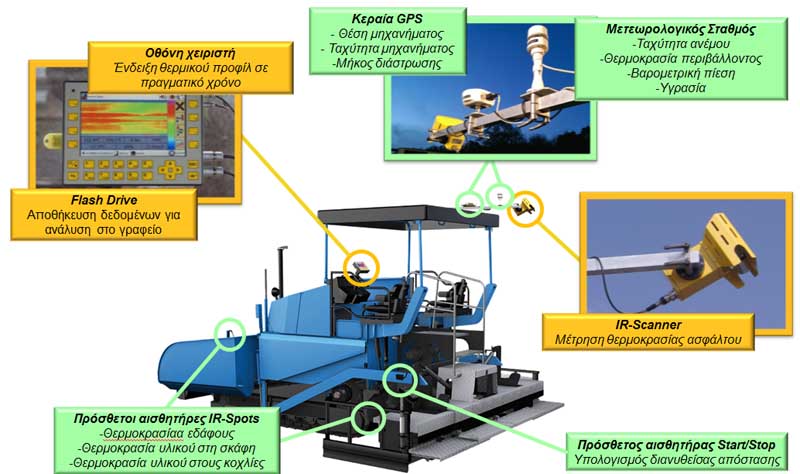

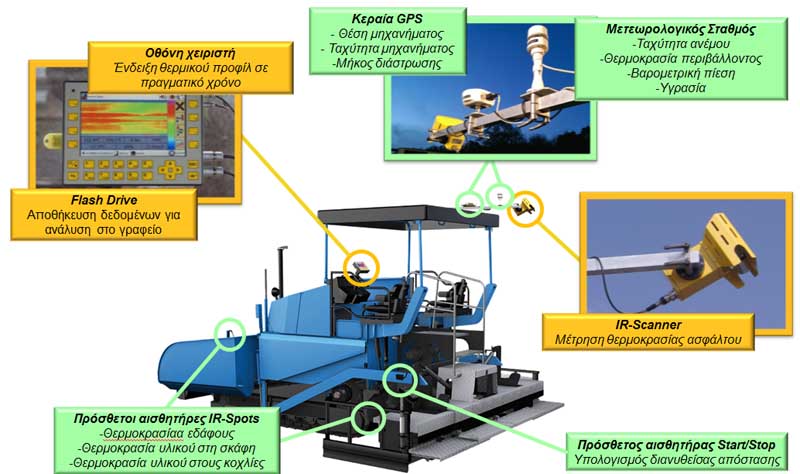

Its characteristics Pave- IRTM Scan?

- Quality control layering in real time

- Record it thermal profile of the road surface

- Display of the thermal profile on screen close to the operator

- Register and Save of the stratification data

- Analysis data from counterparty office software

- Creation reference (As-Built) with all layer data

Benefits for Construction Companies – Paving Contractors

- Ability to be detected failures during laying

- It allows her correction malpractices in real time

- Continuous monitoring provides confirmation of the corrections we made

- Evidence that there were no significant temperature changes during laying

- Evidence that the temperature of the material was within within of the specifications throughout the laying process (boats, screws, plate)

Benefits for Aproject contractors – Supervision services

- Evidence layering quality control

- Complete thermal profile of laid surface (including environmental conditions)

- Data checking and investigation specific areas of possible failure/malfunction

- Autopsy of failure areas at points of known coordinates from the GPS system

- Provision additional bonus to contractors using pavement quality measurement and recording systems